Pyroceram is a heat resistant glass ceramic that can tolerate exceptionally high temperatures.

Pyroceram glass sheets.

It can be manufactured in ogival shapes hemispheres pressware sheets and various machined shapes.

The chemical and physical properties of pyroceram have been tested in accordance to nf din en or iso specifications.

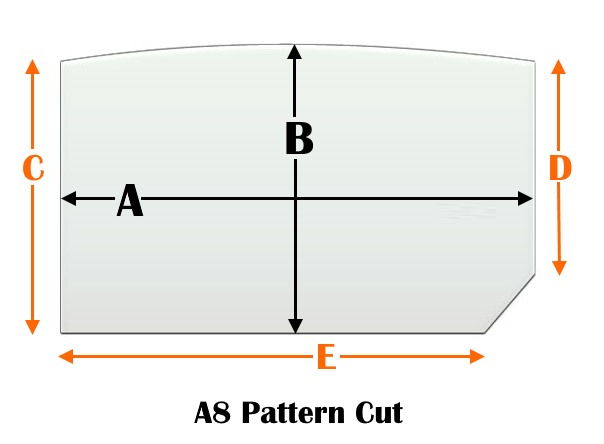

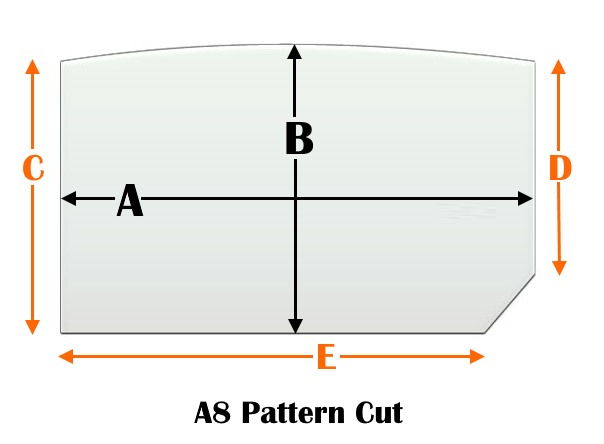

This is a custom made standard rectangle cut ceramic glass that is suitable for most pellet wood and coal stoves or inserts up to 36.

Since its creation manufacturers have extended the use of pyroceram to commercial ovens broilers heat insulators anti aircraft missiles and architectural lighting.

Pyroceram is a transparent ceramic glass that is an excellent transmitter of visible light and creates a warm atmosphere with a light amber colored tint.

The ability of glass ceramic to withstand sudden heating cooling or both without cracking shattering or exploding out of the frame.

Corning pyroceram glass ceramic material is opaque light gray in color and has high strength high elastic modulus and uniform dielectric properties.

Pyroceram was first implemented to create casserole dishes and saucepans.

This amber transparent ceramic material is ideal for high temperature applications.

Ceramic glass is also known as pyroceram neoceram and robax brand names.

Ratings are assigned in levels from 1 to 8 with a level 8 rating being the highest able to stop a 7 62mm rifle lead core full metal copper jacket.

Ceramics tolerate continuous exposure to high temperatures without fear of damage.

This rectangle cut ceramic glass is suitable for most pellet wood and coal stoves or inserts up to 36.

In actuality it is a transparent version of ceramic.